Click this messge to hide it.

- Rigid high density polypropylene with honeycomb construction

- Overall wall panel thickness approximately 13mm

- Decorative two tone moulded wood profile design

- Hollow box profile corner posts for greater strength and rigidity

- Spacious internal area

- Hollow galvanized steel box profile ridge support bars

- Powder coated metal ridge cap

- Powder coated metal door frame

- Single hinged door approximately 2'5" wide x 5'8" high (730mm x 1720mm) in the 3'11" wide wall

- Door can be locked with a padlock (padlock not included)

- Ventilation panel in front and rear gable

- Non opening window glazed with plastic

- Eaves corner plates to ensure maximum strength and rigidity

- Strong galvanized steel foundation rail

- Low threshold doorway with ramp for easy access

- Corner brackets

- Metal base anchors

- Gable cladding panels attach with rigid H profiles with metal strengthening bars at the joints

- UV resistant

- Low temperature resistant

- Suitable for indoor or outdoor use

- External cladding size 3'11" wide x 5'11" deep (1200mm x 1800mm)

- External roof size 4'5" wide x 6'4" deep (1340mm x 1920mm)

- Eaves height 5'8" (1730mm)

- Overall ridge height 6'8" (2040mm)

- Overall weight excluding floor approximately 48kg

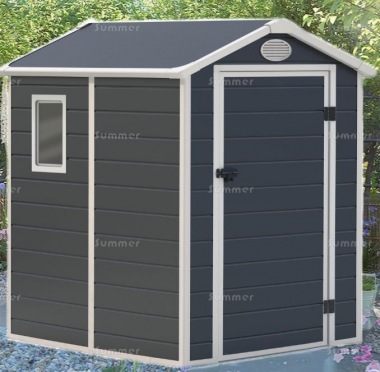

THIS HYBRID SHED: This modern hybrid shed features twin wall polypropylene cladding combined with strong galvanized steel framework. Numerous specially designed brackets and clips further improve the strength and longevity of the building. The clever design and choice of materials results in a shed which is durable and virtually maintenance free.

TWIN WALL POLYPROPYLENE: Twin wall polypropylene is virtually unbreakable and very practical. The rigid, high density polypropylene features a honeycomb construction with narrow flutes for extra strength. The overall panel thickness is approximately 13mm. Polypropylene is also low temperature resistant and provides good insulation during the winter months. Twin wall polypropylene cladding is stronger than the flimsy single skin cladding panels supplied with some plastic sheds.

CLIP FREE CLADDING DESIGN: The unique cladding design ensures that the polypropylene panels are held in place continuously along every edge including the top and bottom edges. With most plastic sheds the glazing is retained along the vertical edges only and the top and bottom edges receive little or no attention.

STRONGER GABLE WALL CLADDING: The pre-assembled gable cladding panels are attached to the walls using rigid H profile bars at the joints. These box section pieces contain a metal strengthening bar for additional rigidity.

LOUVRED VENTILATORS: The front and rear gables are fitted with louvred vents for improved ventilation. This reduces heat, humidity and condensation, which is better for anything being stored inside the shed.

SIZES - LENGTH AND WIDTH: Sizes are sometimes rounded to the nearest nominal size for ease of reading but the correct external wall sizes are listed alongside the price. The first dimension listed is the width and the second dimension is the length. The width refers to the angled gable walls at the front and rear including the door wall. The length refers to the side walls. The sizes listed are the external wall sizes. These sizes do not include the roof overhang. Many other suppliers quote the overall roof size which is much larger. All sizes are approximate.